Source: http://www.3ders.org/

Author: staff

3D printing techniques are being adopted with increasing regularity in surgery of all kinds, and more and more patients are seeing a hugely improved quality of life thanks to the unique benefits of the technology. The most recent success story took place in the UK, where a patient’s jawbone was entirely reconstructed using bone from his leg. The pioneering surgical procedure made use of 3D printing at various different stages.

Stephen Waterhouse was diagnosed with throat cancer eight years ago, and underwent chemotherapy and radiotherapy in order to fight it. The treatments were a great success and his cancer went away, but they had an unfortunate side effect. His jawbone had started to crumble, and emergency surgery was required before it completely disintegrated. The 53-year-old was taken to Royal Stoke University Hospital, which had purchased a new 3D printer just two years previously.

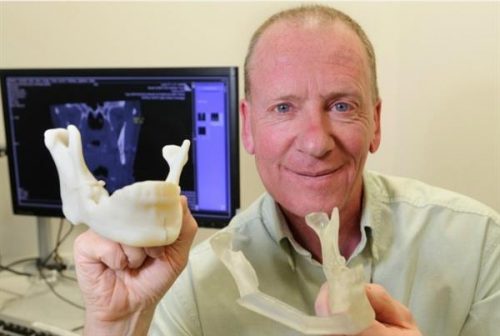

Costing the hospital trust around £150,000 (about $188K), the machine is the only one of its kind in the country, and was a crucial part of the effort to save the patient’s jawbone. A 3D model was designed from a scan of his remaining intact jaw and printed out as a mold, which was then used to reconstruct the jaw using bone taken from his fibula. The operation lasted around 12 hours and was a great success.

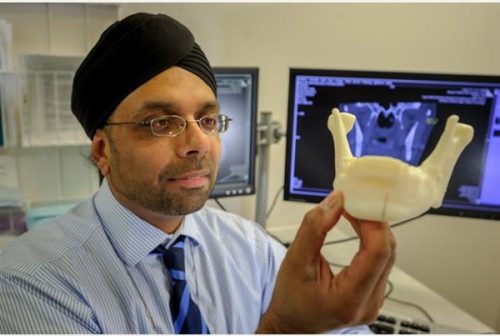

According to Daya Gahir, consultant in maxillofacial and head and neck surgery, the hospital does “at least 40 major head and neck reconstructions per year. Around 10 to 15 cases will be done in this way using the printer.” The procedure is very intricate, and the hospital’s purchase of the 3D printer has revolutionized the way his team operates. “Some of the leg bone was taken then reshaped, as you have to replace bone with bone. We took away some of the skin from the leg as well and replanted it back into the neck. A face is not easy to reconstruct, it is intricate.”

New software for the 3D printer was developed last year, which allows the whole process to be planned and carried out within the hospital. Without this, Stephen may have had to travel to Germany for the operation to be completed, according to Gahir. Using the 3D printer in this way saves a lot of time and effort for patient and medical team alike, as well as cutting costs. Around £11,000 is saved for each case by carrying out the whole surgical process on-site.

Stephen is still in recovery and has praised the care he is receiving from staff, as well as the effectiveness of the surgery. “I am so pleased with the results,” he says, “you can’t tell the difference between the two sides of my mouth.”

Leave A Comment

You must be logged in to post a comment.