Source: www.onlinetmd.com

Author: Elizabeth Engler Modic

Morgan Technical Ceramics (MTC) worked with the UK-based University of Hull to develop a new valve used to restore vocal function for patients with throat cancer. The new tracheo-oesophageal fistula speech valve uses Zyranox biocompatible Yttria partially-stabilized Zirconia, specifically developed for surgical implant devices.

A small silicone valve connecting the windpipe (trachea) and the throat (oesophagus), consists of three ceramic components that must be precision-manufactured so they work together properly. The image shown above is not of the actual Avoco Medical valve, but an image of where implantation of the valve will be.

The iterative design process for this innovative valve included a close collaboration, featuring consultation on materials, prototyping to test the design, and precision manufacturing to meet the extremely tight tolerances required.

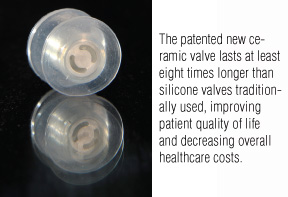

The patented new ceramic valve lasts at least eight times longer than traditionally used silicone valves, improving patient quality of life and decreasing overall healthcare costs. The device is to go to market via the spinout company Avoco Medical Ltd.

Project Goals

Avoco Medical was seeking to improve upon a commonly used speech restoration system for throat cancer patients, which uses a small silicone valve connecting the windpipe (trachea) and the throat (oesophagus). Air, powered by the lungs, diverts into the throat, which vibrates and results in fluent speech. Traditionally the valve is from silicone rubber, but the material exposure to hostile and non-sterile environments results in development of a biofilm on the surface. This biofilm causes valve performance to deteriorate, necessitating an uncomfortable and costly valve replacement procedure about every three months.[1]

Precision Manufacturing

The company was seeking a way to replace the silicone with ceramic, a more attractive material because of its stability, biocompatibility, and compliance. With its hard, impervious surface, ceramic is more resistant to the hostile environment found in the throat.

The medical device company had a design concept for the new valve, a three-piece component with a front and a rear casing, and a dart-shaped component inserted into the top and bottom casing. The dart moves forward and backward to close the valve. The overall size of the valve is less than 10mm.

The new tracheo-oesophageal fistula speech valve uses Zyranox biocompatible yttria partially-stabilized zirconia, specifically developed for surgical implant devices.

MTC became involved in the project about two years ago; when Avoco Medical sought out the Rugby, UK, plant for their experience with ceramics, design, and precision manufacturing. The plant, which manufactures advanced ceramic components, began by developing five scale prototypes of the valve. The material used is Zyranox biocompatible yttria partially-stabilized zirconia, a very high purity zirconia-based material, produced specifically for surgical implant devices. It contains 99.9% zirconium oxide (ZrO2), with yttrium oxide (Y2O3) and hafnium oxide (HfO2) in combination. Initially chosen because of proof for high resistance to biofilm during extensive laboratory testing was Zyranox zirconia ceramic, originally designed in the 1980s and for use in femoral heads for hip joint replacements.

However, the material also has another distinct advantage – MTC already had an FDA master file and ISO 13485 approval for the zirconia material, so they could demonstrate the material’s biocompatibility beforehand, a boon to the design process. The material also exceeds the requirements of ASTM F1873i and ISO 13356ii. The demonstrated biocompatibility meant that the company did not have to go through a full validation process demonstration; they simply had to prove that the device is safe and performs as specified.

MTC was able to show a failure mode analysis (FMA) to support the use of the material for a medical device. They had examined all the potential hazards and had a risk mitigation plan in place.

“When we design a new component we look at all the key criteria and features, testing to see that the design meets requirements,” says Yannick Galais, commercial manager for MTC’s Rugby, UK, site. “We make sure that every aspect of risk is satisfied.

“The new speech valve includes three ceramic components that must be precision-manufactured so they work together properly. The difficulty here was to design an assembly that would encapsulate the dart but allow it to move freely,” Galais continues.

He notes that the tolerances are tight and must be precise.

“Controlling the fit and clearance between the different components is critical. MTC has the ability to manufacture the parts to tight tolerances and complex geometries, which is essential to providing high quality, reliable valves,” Galais explains.

Similarly, the surface finish of features is key to ensuring the component can slide without catching. MTC worked on tooling to achieve the most appropriate surface roughness parameter (RA) to permit the proper motion of the dart.

To avoid secondary operations that add to costs, MTC had to develop a manufacturing process that would result in a finished product, with the proper fit, with one machining operation. This was a challenge, since manufacturing of each of the three components was individually, but had to fit together. The goal was to achieve repeatable tolerances to make the assembly work. To meet this goal, MTC did a significant amount of preliminary work mimicking the fit and evaluating the surfaces in contact without the full assembly to make sure that each worked. They did a mockup of one part, then another, and then the third. When they were sure that all the design experiments worked together, they completed the full assembly.

The front of the dart provides a curved sealing surface that prevents fluids from the throat going into the lungs, so designers had to make sure there were no leaks in the front face of the dart. Another challenge was that the back of the dart contains the three flanges that move in the valve body. The designers prepared a number of iterations on the shape of the flanges to make sure they could move without sticking to the housing. Mockups were prepared of different phases, then production of a full-scale assembly to test that all the previous concepts worked. This meant they could fine-tune or tweak the design without having to change other components.

During the yearlong design process, MTC worked on a number of design iterations – as the realization came that some features were not achievable or would not meet the original movement requirements. They reshaped the features in collaboration with Avoco Medical, working on amendments needed to achieve the final product.

Zirconia ceramic components have a hard and impervious surface, which discourages the biofilm that reduces standard silicone rubber valve performance. It has proven to be highly resistant to biofilm during extensive laboratory testing and the ceramic valves should last more than two years – at least eight times longer than silicone ones.

Leave A Comment

You must be logged in to post a comment.